In general, a small to medium size blow molding machine can produce water tanks of up to 500 liters and can cost anywhere from $50,000 to $150,000. However, larger machines with a capacity of up to 10,000 liters can cost well over $1 million.

What capacity of water tank do you produce? How many layers of plastic water tanks?Produce water tanks with different capacities and layers, the price of the machine is naturally different.

The best deal is to get the highest quality machine and services at the lowest price.

This article is intended to help you know how much it will cost to buy a water storage tank blow molding machine. To help you determine whether a blow molding machine is right for you!

The price of a water tank blow molding machine can vary greatly depending on several factors such as the type of the machine, size, production capacity, features, and quality of the machine. etc.

1, Production capacity

The production capacity of a water tank blow molding making machine is an important factor in determining its price.

There is no doubt that machines with high production capacity usually cost more than machines with low production capacity.

If there is high demand for such machines, their prices may increase due to market competition forces.

2, Automation level

The level of automation of water tank blow molding making machine will significantly affect its price.

Water tank Blow molding machines can range from fully manual machines to fully automatic machines. Manual machines require more human labor and intervention, while fully automatic machines require minimal human intervention and can run continuously.

Machines with a higher degree of automation usually have automatic mold change, material feed systems, and other functions. These features can significantly increase the production efficiency of the machine. However, Increased automation comes with higher costs. And as a result, they are much more expensive than semi-automatic or manual machines.

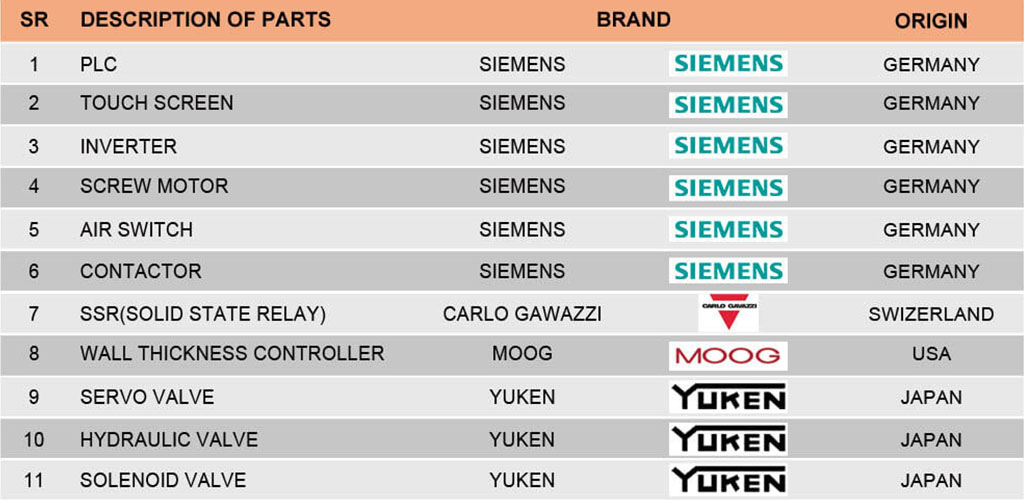

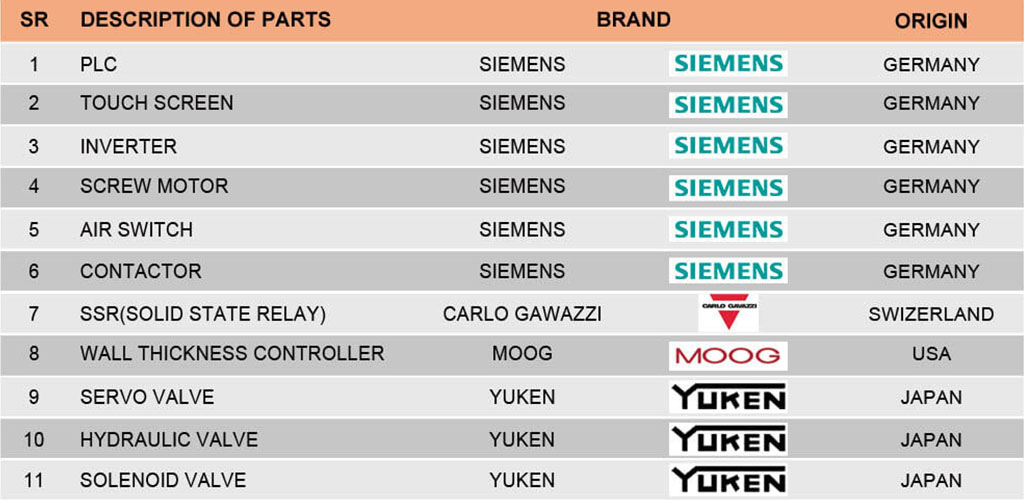

3, Machine Configuration

The quality of materials used in the construction of the machine can impact its price.

The configuration of a machine can vary depending on the manufacturer, model, and intended use of the machine. For example, a basic configuration of a water tank blow moulding machine may include standard components and features, while a more advanced configuration may include additional functions that enhance the performance of the machine.

The cost of a machine will increase as more features and options are added to the configuration. This is because the manufacturer will have to invest more resources in developing, designing, and producing these functions and options. Such as advanced control systems or specialized molds. Machine’s competitive advantage: High efficiency and saving energy. More advanced configurations can provide greater value to the customer, and they can improve the durability and service life of the machine.

4, Brand reputation

Well-known and respected brands may charge more for their machines compared to lesser-known brands. But Brand means ‘Reliability’. Buying a water tank extrusion blow moulding machine of a famous brand means buying the perfect machine in all aspects because reputed brands are quality system-certified manufacturers and have government approvals.

Consumers are often willing to purchase machines from reputable brands. They know that the brand has a track record of producing high-quality machines that are less likely to break down or require expensive repairs, and they may also expect better customer support and after-sales service.

5, Country of origin

The country of origin can affect the price of water tank blow molding machine due to differences in labor and manufacturing costs.

For example, water tank blow molding machines manufactured in China or other Asian countries tend to be cheaper than those manufactured in North America or Europe. This is because labor and production costs are generally lower in these regions, allowing manufacturers to offer their machines at a lower price.

6, Supplier or distributor

The price of water tank blow molding making machine can also vary depending on the supplier or distributor.

some suppliers are real original manufacturers, factory direct price, and may offer lower prices. However, some are distributors, they do not have production workshops at all, and may charge extra for their services.

It's important to note that the cost of the machine is just one of the many expenses. Other costs include electricity power, labor, building size, cost of production...etc. , The water tank blow molding machine manufacturer may have to charge a higher price to cover their costs and make a profit.

Hearing this, you will feel that the price of a water tank blow molding machine is very expensive. You may want to save costs to buy a used,low-price hollow blow molding machine. However, second-hand equipment, although cheap, there is a lot of trouble. Later repairs may cost more than saving at the time.

It's always best to consult a reputable manufacturer or supplier to get an accurate quote based on your specific needs and requirements.

Your Water Tank Blow Molding Machine Manufacturer Worth Choosing-Repeat Buyers Choice

To Help you create quality, cost-effective products.

The Main Application of water tank Blow Molding Machine