What should I pay attention to when buying a blow molding machine? How do I choose a cost-effective plastic blow moulding machine?

Here are 12 things to consider:

1, Type of blow molding machine

There are different types of blow molding machines, such as extrusion, injection, and stretch blow molding machines. You should consider which typ

e of machine is best suited for the type of product you plan to produce.

Extrusion blow molding machines: These machines use an extruder to melt the plastic material and create a continuous tube, which is then inflated and shaped in the mold.

Injection blow molding machines: These machines combine injection molding and blow molding to create plastic parts in one step. The plastic material is first injected into a mold to create a preform, which is then transferred to a blowing station where it is inflated and shaped in the final mold.

Stretch blow molding machines: These machines use preforms made by injection molding or other methods, which are then stretched and blown in a mold to create the plastic bottles, jars, and other containers.

2, Production Capacity

Many manufacturers incorrectly report the theoretical production capacity, and this output capacity cannot be achieved in actual use. A general rule of thumb is the production capacity of the machine you are going to buy should be 25% more than your demand.

For low cost and mass production, should choose a fully automatic, high-speed, high output, stable and reliable blow molding machine.

2, Energy Consumption

Energy consumption is one of the biggest costs for a blow molding operation. The production cost directly determines the final profit. Therefore, saving energy is an extremely important factor when buying a blow molding machine.

Look for a machine that is designed to be energy-efficient and can reduce your operating costs over time.

3, Full-automatic VS Semi-automatic

The semi-automatic blow molding machine has the characteristics of small investment, simple maintenance, low output, and strong manual intervention. The full-automatic blow molding machine is characterized by simple operation, high price, high output, labor saving, and high enterprise benefit.

If your product demand is small, and labor cost is low just go for semi-automated, if your labor cost is high go for fully automated. Certainly, you need to make a decision based on your situation.

4, Enough locking force

Clamping force in blow molding refers to the pressure needed to hold the mold closed during the manufacturing process. The pressure is required to ensure the molten plastic reaches every part of the mold evenly.

When the Molten plastic material is injected into the metal mold cavity at high pressure, it will create high pressure inside the mold. So, if there is not enough locking force, the mold will be open and raw material will leak, even causing safety accidents. The clamping device plays an important role in the extrusion blow molding process.

5, Mould

For any plastic molding program, the mould building is the most expensive and time-consuming part of it. The design of the mold is critical to the success of the blow molding process. It is recommended that molds and machines be purchased from the same manufacturer. Because it’s easy and convenient to test the molds.

Blow molding molds can be made from a variety of materials, including aluminum, steel, and composite materials. The choice of material depends on the requirements of the part being produced, the production volume, and the budget.

6, Auxiliary machinery

The novice buyers of blow molding machines may not be clear that blow molding machines are divided into bare and auxiliary machines, which can not be separated from each other.

Auxiliary machines are a set of accessory and peripheral equipment for blow molding. Including air tank, cooling chiller, mixer, air compressor, cooling tower, crusher, and shredder. It’s an integral part of the extrusion process to improve or optimize the extrusion process efficiency and ease of operation. You can choose auxiliary machines according to the recommendations of the machine manufacturer.

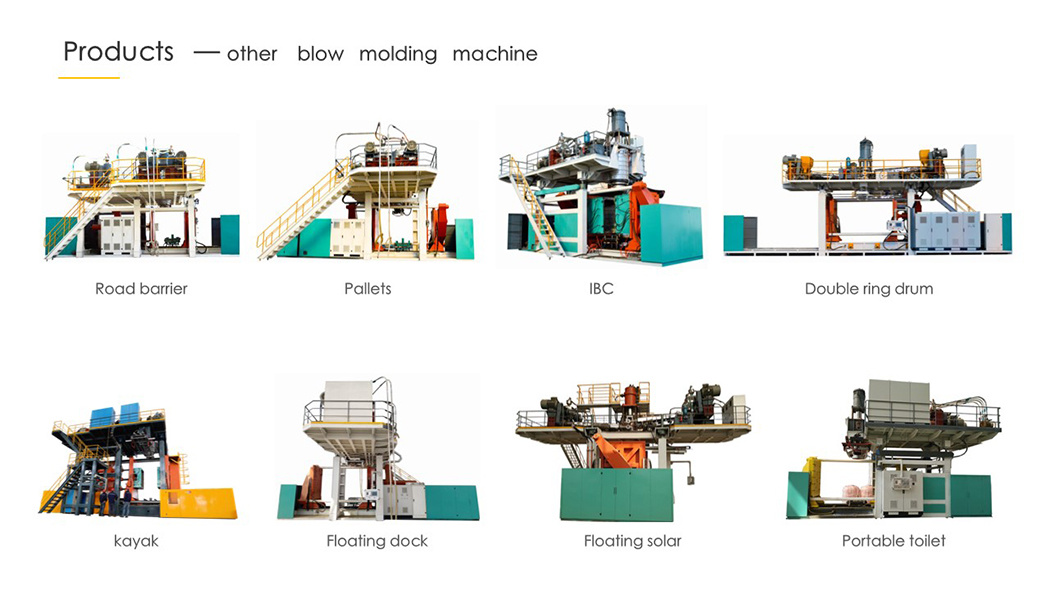

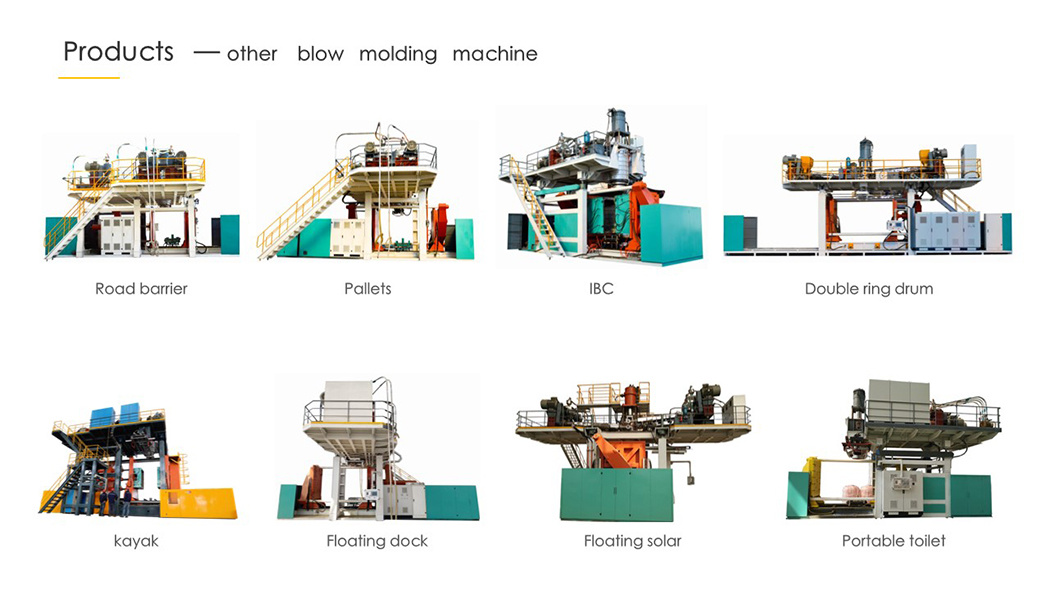

7, Case Situation

The case is the main method to show the production technology of the blow molding machine.

There has technology but no actual customer cooperation production case, which does not indicate that the blow molding machine can maintain stable operation in the long-running process.

8, Price

Many factors affect the price of blow molding machines. Such as, machine configuration, the volume, size, and layers of the products. The cost and time spent in production are also different for different equipment models. Pay attention to the following points:

First, some manufacturers are real manufacturers, but some do not have production workshops at all. They have to find a factory to do it for you, the price will naturally be more expensive, and the follow-up services can't keep up.

Second, after reading the same performance parameters, many buyers tend to choose a manufacturer with lower prices, but it often means more problems.

Third, it is necessary to ask whether this is the price of the bare metal of the blow molding machine or the price of the complete equipment of the blow molding machine.

You may find that good quality machines are expensive, but eventually, you'll realize that it's worth the investment when you're going to get a high return on that machine. You can consult with the sales manager online to ensure that you choose a blow molding machine with high-cost performance and guaranteed.

9, Support for Customization

Blow molding technology level can meet the production needs of different products to customize the equipment.

We need to communicate with the manufacturer about the specific process requirements of the product and get the program and quotation of the blow molding machine equipment.

10, Production Visualization Service

Show the buyers pictures, videos, or other materials of the order production (Raw material preparation, production start, production completion, testing, packaging, labeling, delivery, etc.). To help buyers know the production state after placing orders, and track the production progress. Some manufacturers will provide machine test reports to ensure quality.

11, Technical Support and After-Sales Service

In the long-term use process, no matter what kind of equipment will appear fault problems, so, you should choose manufacturers with quality guarantee, reliable and perfect after-sales service. This guarantees your benefits, avoiding unnecessary losses and effects. An after-sales staff trains the buyer operator or dispatches an engineer to install and adjust the machines. Free replacement of machine parts if quality problem.

12, Reliable Manufacturer

A reliable and professional blow molding machine equipment manufacturer usually has advanced professional level, relevant industry qualification certification (CE, IS09001, SGS, etc), a perfect service system, standardized factory scale, and good customer reputation. These are the judgments of the quality manufacturer.

Besides, I suggest you should consider buying a blow molding machine of a well-known brand, because“Brand"means"Reliability". Reputed brands are certified manufacturers and have government approvals.

Qingdao Yankang Plastic Machinery was the first company to research and developed 5 layers and 6 layers of super large hollow blow molding equipment in the world. In 2016, Yankang also developed the first set of 20000L equipment in the world, which has exceeded 15,000L of Germany.

In a word, we should first know our own production needs, understand the differences in configuration, performance and parameters of different blow molding machine products, and buy the corresponding model of blow molding machine according to the produced plastic products.